|

|

|

|

|

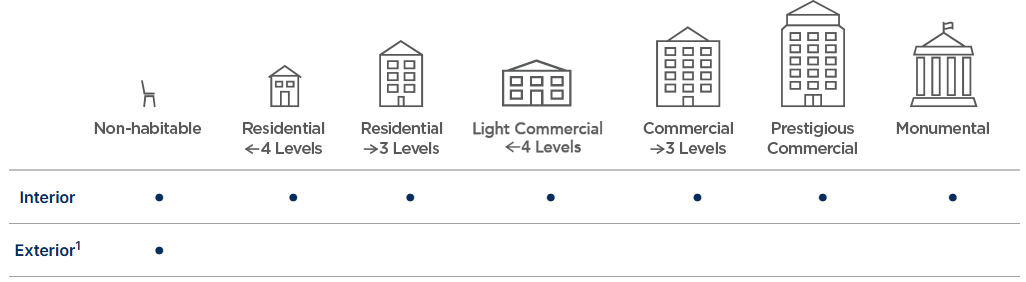

It is ideal for use:

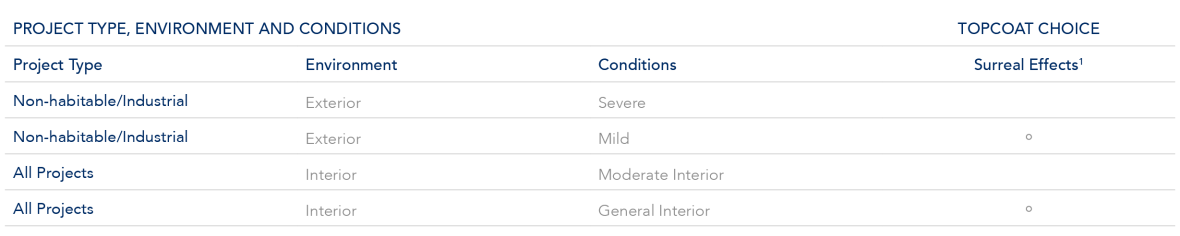

Surreal Effects is only suitable for coastal environments >500m from the high tide line and are NOT suitable in strongly acidic environments so PH must be between 5 and 9.

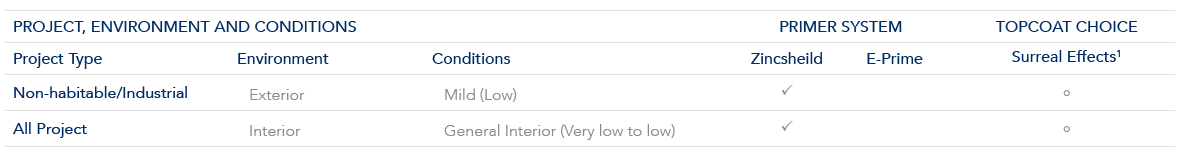

1 Surreal Effects Graphite Sarouk is a modified epoxy and should only be used in interior environments

The pre-treatment process must be capable of meeting the performance outputs as described in AS3715 Compliance to appropriate process parameters is essential in ensuring compliance to etch, conversion coating weights (time/concentration) and conductivity of the final rinse.

The etch process is a very important stage of pre-treatment and close consultation with your pre-treatment supplier is strongly recommended to ensure optimum adhesion & corrosion resistance is obtained. As an approximate guide:

This is the next pre-treatment process for aluminium to ensure that it is suitably prepared for coating. It is recommended that Chrome conversion weights shall be a minimum of 431mg/m2, but advice from pre-treatment suppliers should be taken into consideration.

Final rinse is to ensure optimum surface preparation prior to coating.

Care should be taken with handling to ensure health and safety measures are met and that the substrate is not contaminated.

If your site uses a dry off oven to assist in the pre-treatment process, consult your pre-treatment supplier for advice, but generally;

Metal Temperature:

210° : 4 mins minimum

200° : 5 mins minimum

180° : 8 mins minimum

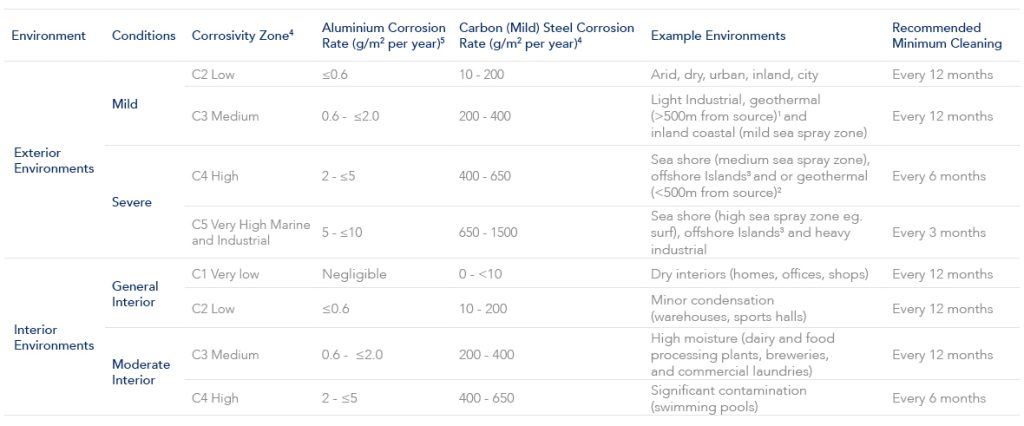

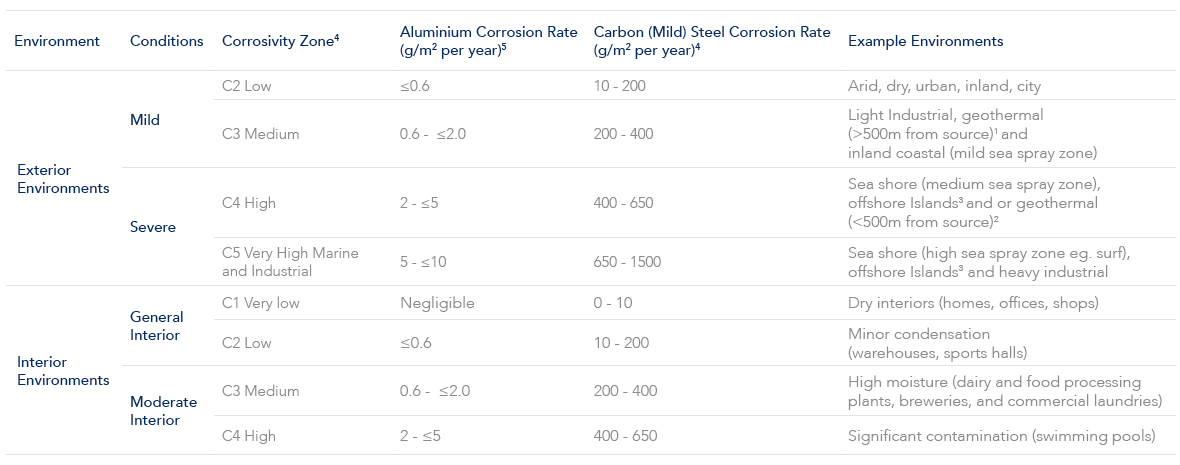

The table references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories.

Use the following table to help identify where Surreal Effects can be applied on aluminium projects. Refer to the conditions information to determine the environment that your project will be exposed to.

Use the following table to help identify where Surreal Effects can be applied on steel projects. Refer to the conditions information to determine the environment that your project will be exposed to.

Use the following table which references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories To pinpoint your projects corrosivity zone this table should be used together with the corrosivity zone maps contained within AS 4312 .

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project. Call 13 24 99

Colours displayed should be used as a guide for your colour selection.

Always confirm your colour choice with a production line prepared swatch for final colour approval.

The Surreal Effects range is a collection of functional and decorative textures and ripple effect finishes, designed to conceal surface imperfections, delivered with tough polyester thermosetting powder.

Flat

90133641

Gloss

90151608

Gloss

9017907Z

Flat

90137543

Gloss

9014461Z

Gloss

9012015Z

Gloss

9016535Z

Gloss

9017951Z

Gloss

90136612

Gloss

90185184

Gloss

90182757

Gloss

90150223

Flat

90132679

Gloss

90185159

Gloss

90150003

Gloss

90185040

Matt

93551677

1 Surreal Effects Graphite Sarouk is a modified epoxy and should only be used in interior environments