Dulux Powder Coatings are an ideal choice for the long term protection of mild steel items for your next project and provide assurance through the issue of Steel Shield™ Warranties.

The Steel Shield™ warranty will only be issued on the following substrates: mild steel, bright/semi bright steel, black/blue steel. All other steel types including galvanised coated steel are not warranted under the Steel Shield™ Warranty Program.

| WARRANTY | STEEL (MILD) | BRIGHT / SEMI BRIGHT | BLACK STEEL | BLUE STEEL |

|---|---|---|---|---|

| Steel Shield | • | • | • | • |

The Steel Shield™ Warranty is made up of two key components, a colour warranty (for fade and chalking) and a corrosion warranty.

The Steel Shield™ Colour Warranty is your assurance that the colour integrity will be maintained. It is made up of two components: Fade1 & Chalk2

The Steel Shield™ Corrosion Warranty is your assurance that the substrate will not corrode. The powder coating will not corrode for the warranty period from the date the product is applied to the metal.

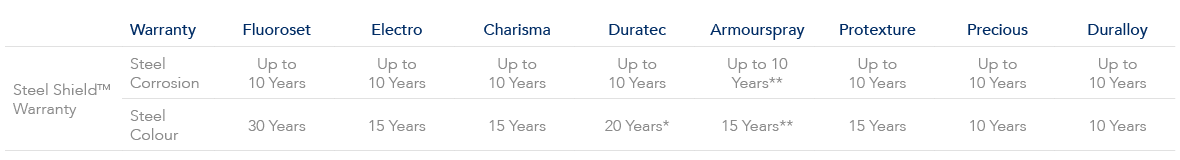

All Dulux premium powder coat products are backed by product specific Steel Shield™ warranties. Below is an overview of the warranty periods by product available from Dulux.

*Excluding Intensity – 15 Years

**The Steel Shield Colour Warranty is not applicable to Armourspray clear products. The Steel Shield Corrosion Warranty only applies to Armourspray clear products when applied over Dulux Protexture, Duratec, Electro & Charisma powder coatings.

Project Suitability

It is important to define your project correctly to ensure the correct product is specified and the performance and warranty is able to be gained for your project.

Both project type and the environment (conditions) will impact on the exposure of the powdercoat to elements such as UV, dirt and salt. For instance, marine and coastal environments are exposed to winds and sea salts, which have a long-term impact on the performance of coating systems due to erosion and weathering, and commercial projects will be exposed to greater environmental impacts, whether they be the usage of the environment or the height of the building.

To ensure products are fit for these environments Dulux recommends suitable products based on the AAMA testing standards. These standards provide a benchmark of product quality that are an assurance that your asset will be protected by a product fit for purpose. For complete details relating to these standards visit aamanet.org

To define projects we utilise three key sources:

1. The building classifications under the Building code of Australia (BCA)

2. Industry standards for powder coatings – Primarily AAMA

3. Environmental condition utilising AS4312 and ISO12944 Atmospheric corrosivity zones in Australia as a guide.

The following tables allow you to identify your project, to look at the appropriate products for the environment, whether it be interior or exterior, the care and maintenance required, and details on our Dulux Accredited Powder Coaters, as only Dulux Accredited Powder coaters are able to issue our Dulux Steel Shield™ warranties.

Important Design Considerations

Dulux Steel Shield™ warranties are available on a wide range of fabricated steel items, but those items must be designed, prepared (pre-treated), coated, fabricated and installed to standard ensuring that the item is fully protected.

It is essential that any item that is coated must be designed and fabricated to ensure:

Use the following table to help you identify your project and the appropriate standard a product should meet for that environment.

Project type definitions:

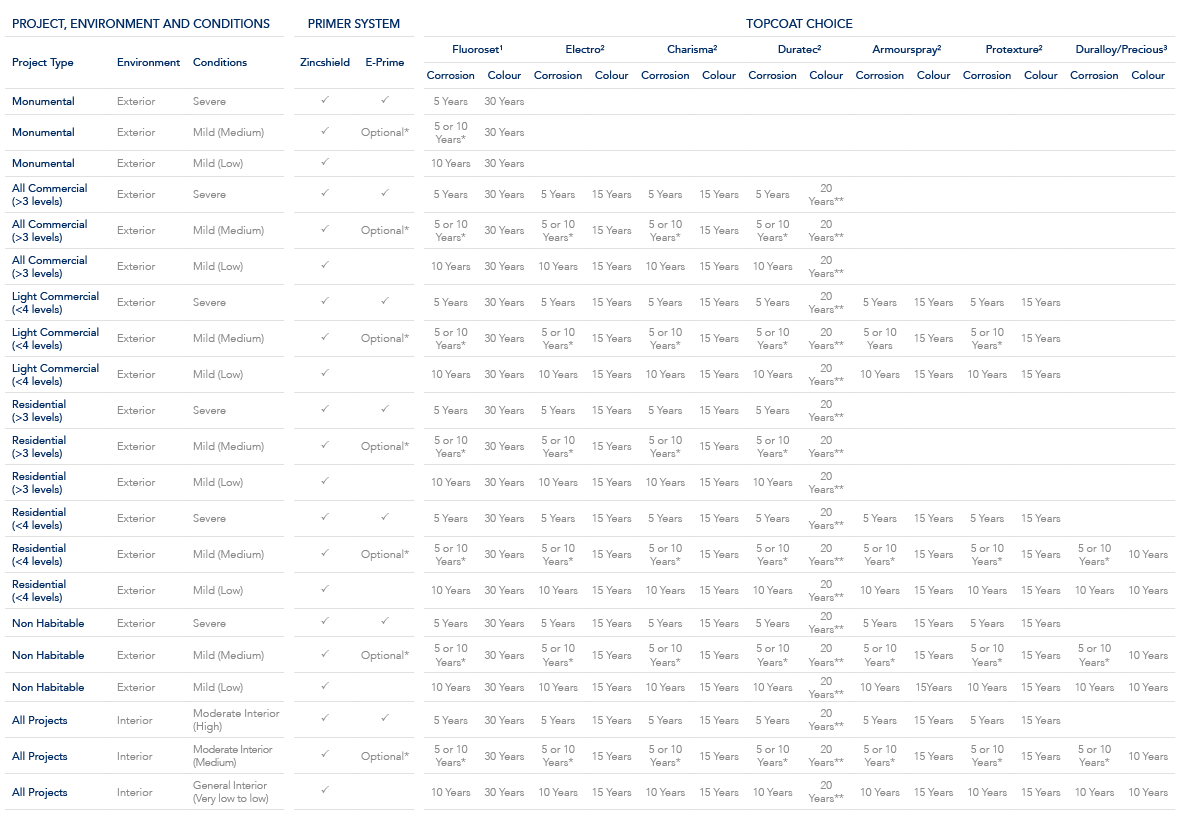

Use the following table to help identify the product choice you have to gain a Steel Shield™ warranty on your exterior project. Refer to the conditions information to determine the environment that your project will be exposed to. Click on the table below for a larger version.

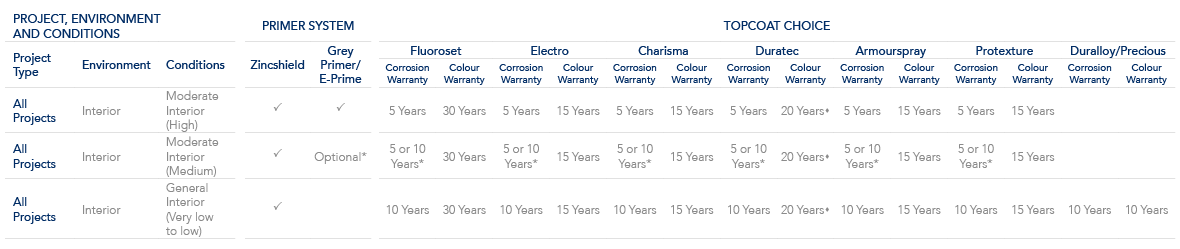

Zincshield is a key component of the Dulux Steel Shield™ warranty systems. Use the following table to help identify the product choice you have to gain a Steel Shield™ warranty on your project and where Zincshield is appropriate. Refer to the conditions information to determine the environment that your project will be exposed to. Click on the table below for a larger version.

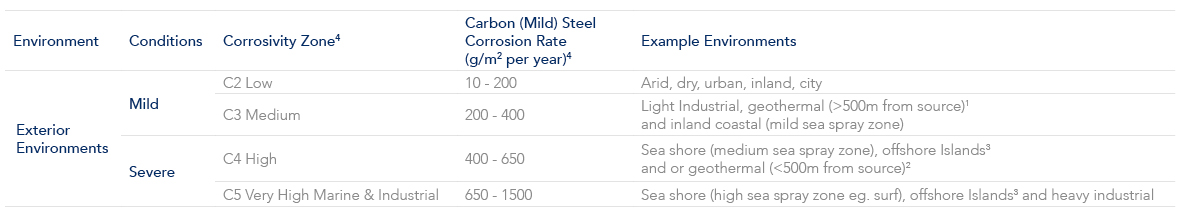

Use the following table which references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories

To pinpoint your projects corrosivity zone this table should be used together with the corrosivity zone maps contained within AS 4312 .

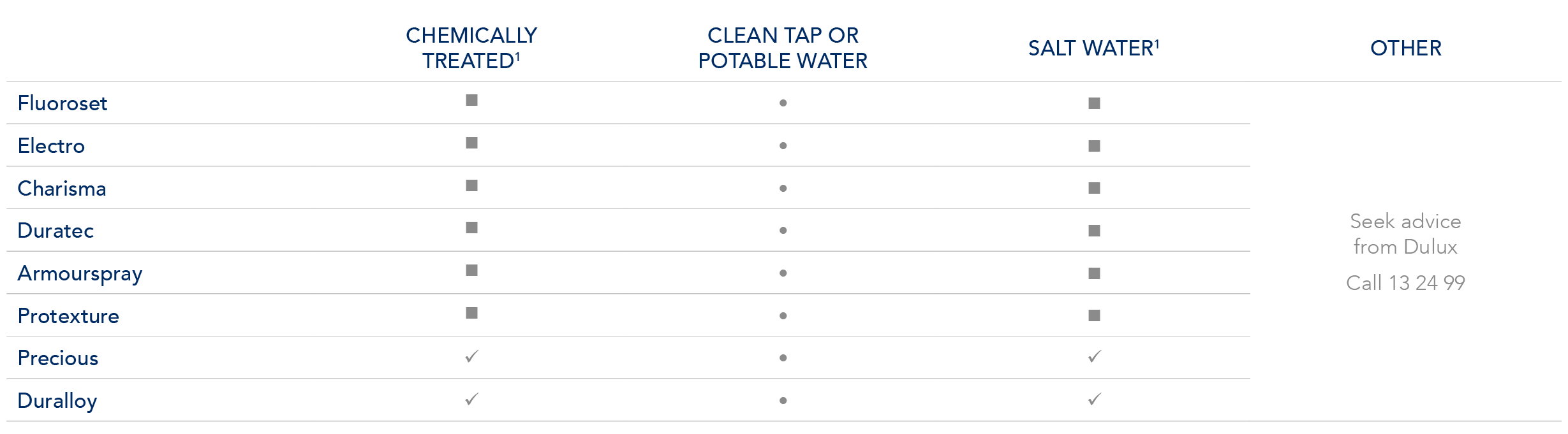

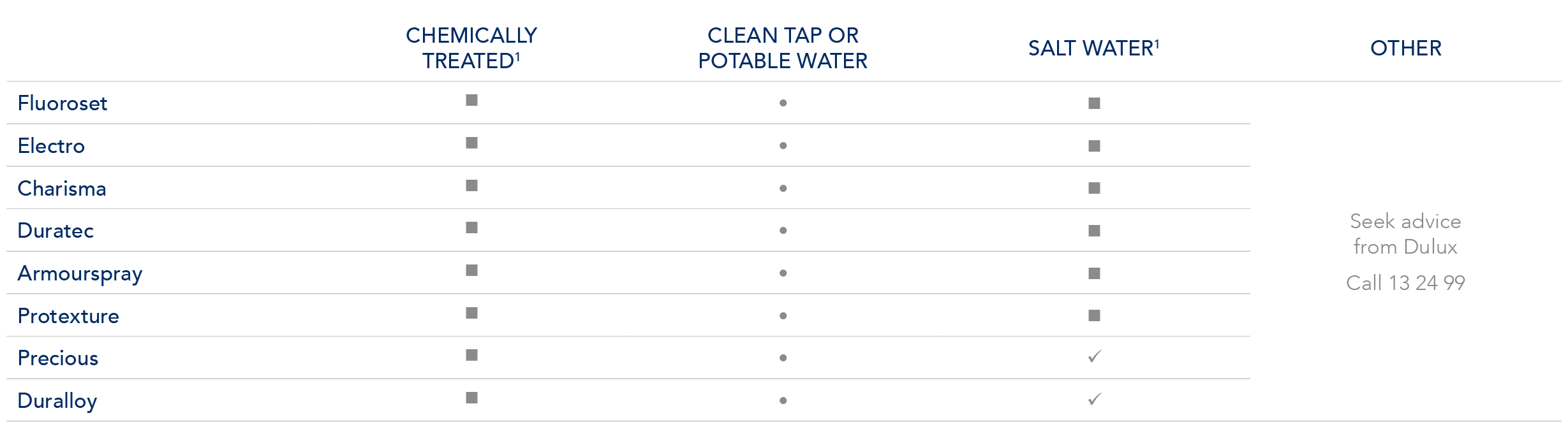

For powder coated assets close to liquids other than the sea, e.g. fences near swimming pools, fountains, outdoor bathrooms or furniture etc, please refer to the guidance below for your product options for your project.

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

Call 13 24 99.

Use the following table to help identify the product choice you have for the interior use of Dulux Premium Powder coatings on your project. Refer to the conditions information to determine the environment that your project will be exposed to.

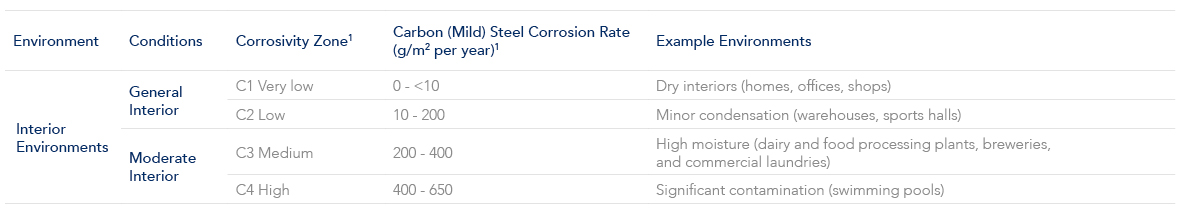

Use the following table which references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories

To pinpoint your projects corrosivity zone this table should be used together with the corrosivity zone maps contained within AS 4312 .

For powder coated assets close to liquids, e.g. fences, windows, doors or furniture near swimming pools, fountains, bathrooms etc, please refer to the guidance below for your product options for your project.

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project. Call 13 24 99

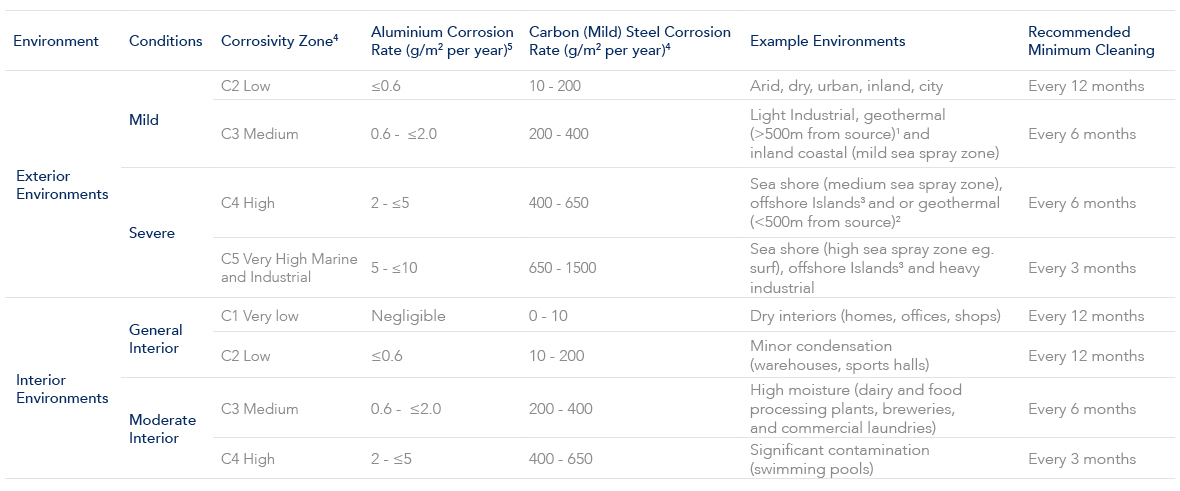

The table references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories.

1. Geothermal environments greater than 500m of a bore, mud pool, steam vent, or other source with a pH between 5 and 9. For A pH outside this consult Dulux.

2. Geothermal hot spots within 500m of a bore, mud pool, steam vent, or other source.

3. All offshore islands including Waiheke Island, Stewart Island, Fraser Island and Pacific islands eg PNG, Fiji, Samoa, Tonga, Tahiti, Noumea

4. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium and Carbon (Mild) Steel are determined by the following standards:

AS 4312 – Atmospheric corrosivity zones in Australia.

AS 2312.1- Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings. Part 1: Paint coatings

ISO 9223 – Corrosion of metals and alloys – Corrosivity of atmospheres – Classification, determination and estimation

5. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium are determined by the following standard:

ISO 9223 – Corrosion of metals and alloys – Corrosivity of atmospheres – Classification, determination and estimation

Only Dulux Accredited Powder Coaters are able to issue our Dulux Steel Shield™ warranties after demonstrating their capability to meet stringent quality conditions and international standards.

For more information, or to find a Alumi Shield approved Dulux Accredited Powder Coater, click here.