About Industrial

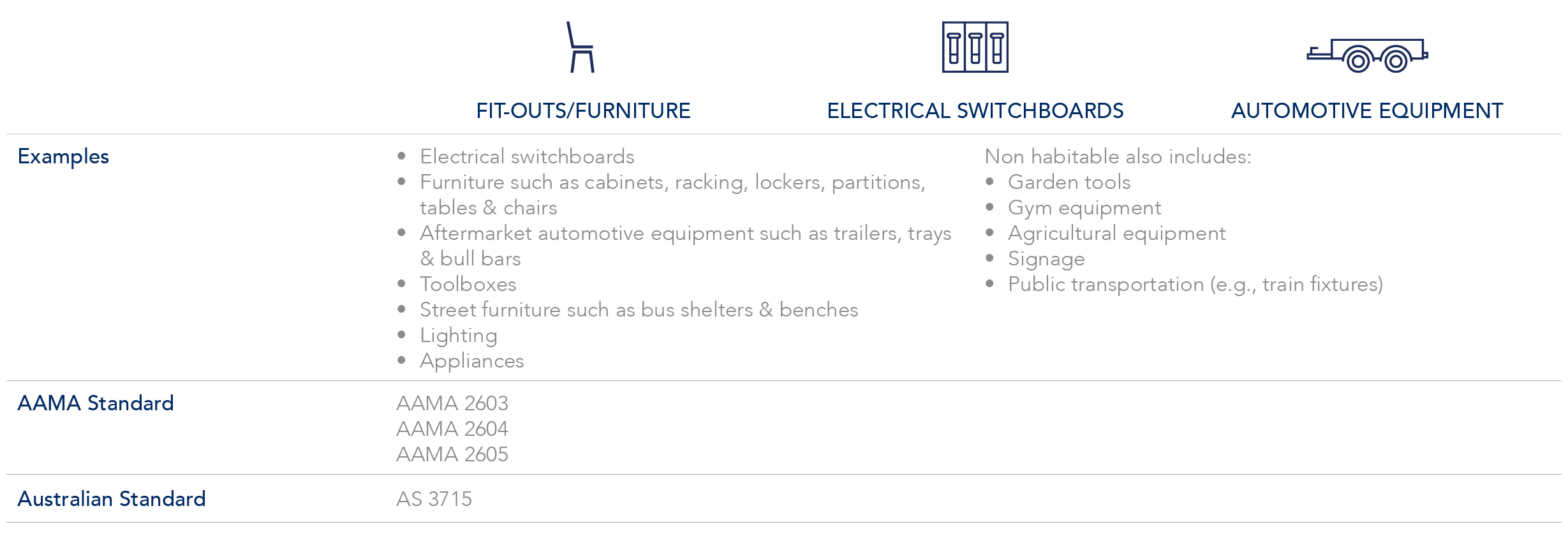

From electrical switchboards and automotive equipment to fitouts, furniture and lighting, Dulux Powder Coatings provide you with the confidence and quality that will make it all worthwhile.

Industrial projects relate to non-architectural items and materials. Examples can be furniture, aftermarket automotive equipment, electrical switchboards, lighting, gym equipment and signage.

*Dulux products that meet AAMA 2603, 2604, 2605 and AS3715 are supported for Dulux Alumi Shield and Dulux Steel Shield warranties on interior and exterior applications when applied by a Dulux Accredited Powder Coater to the warranty specification on recommended project types and conditions.

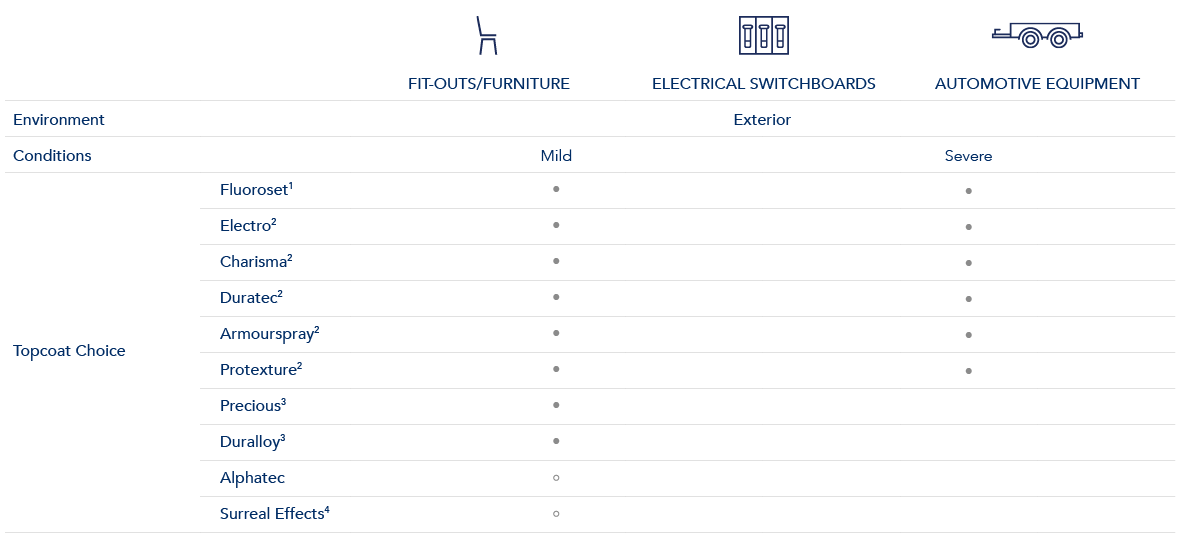

The following table can be used to help identify the product choice you have for the exterior use of Dulux Premium Powder coatings on your non-habitable project. If you have any doubt always check your specification first by calling our advice line on 13 24 99.

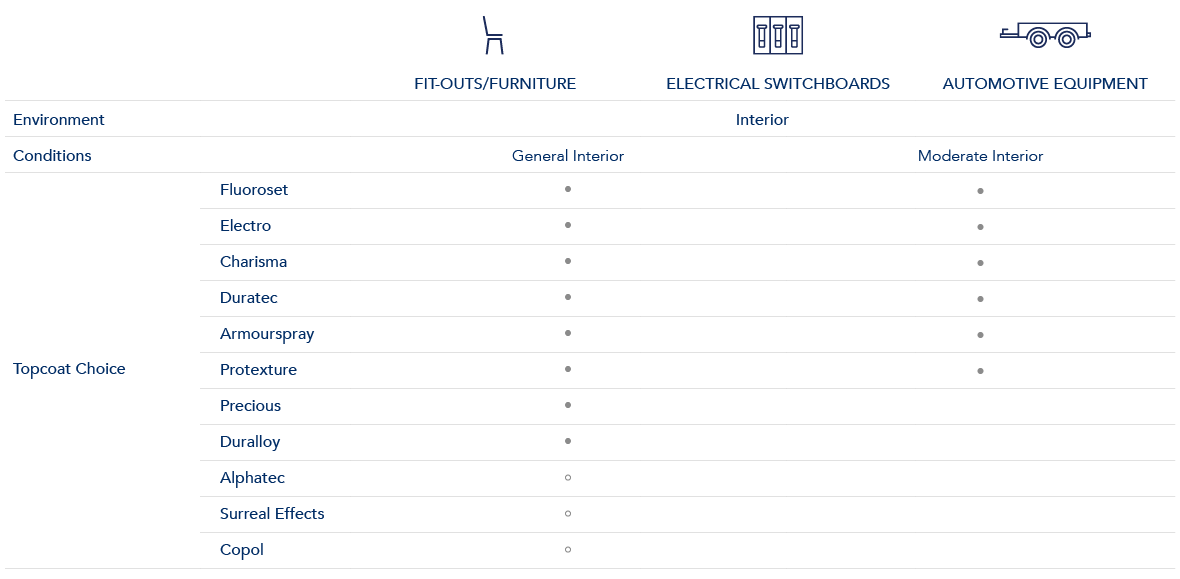

● Alumi Shield™ and Steel Shield warranties are available when applied by a Dulux Accredited Powder Coater to the warranty specification on recommended project types and conditions

○ Non-warrantable

All Dulux powder product are NOT suitable in strongly acidic or caustic environments so the pH must be between 5 and 9.

1. Fluoroset may be suitable in locations <10m from the high tide line e.g. harbours (contact Dulux for advice).

2. Electro, Charisma, Duratec, Armourspray and Protexture, are only suitable for environments >10m from the high tide line.

3. Duralloy and Precious are only suitable for environments >100m from the high tide line.

4. Surreal Effects Graphite Sarouk should only be used in interior environments.

Please refer to ‘Exterior environments close to liquids other than coastal, river and lake salt water environments’ for warranty implications where powder coatings may be in close proximity to liquids.

Information for Perforated and Expanded aluminium:

Alumi Shield™ warranties on perforated and expanded aluminium in exterior environments are available for the following products and conditions:

a. Mild – Duralloy, Precious, Protexture, Armourspray, Duratec, Charisma, Electro and Fluoroset (E-Prime base coat not mandatory)

b. Severe – Protexture, Armourspray, Duratec, Charisma, Electro and Fluoroset (E-Prime base coat mandatory)

For more information about specifications on perforated or expanded aluminium please click here.

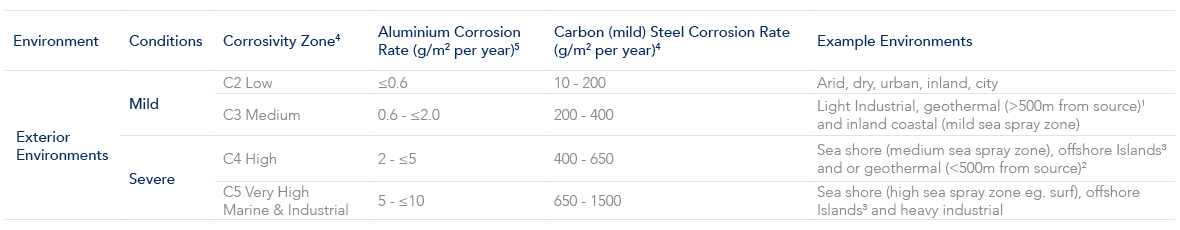

Conditions – Exterior

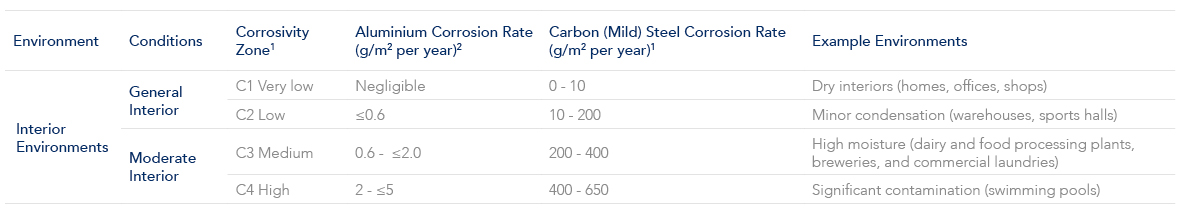

Use the following table which references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories

To pinpoint your projects corrosivity zone this table should be used together with the corrosivity zone maps contained within AS 4312.

1. Geothermal environments greater than 500m of a bore, mud pool, steam vent, or other source with a pH between 5 and 9. For pH outside this consult Dulux.

2. Geothermal hot spots within 500m of a bore, mud pool, steam vent, or other source.

3. All offshore islands including Waiheke Island, Stewart Island, Fraser Island and Pacific islands eg PNG, Fiji, Samoa, Tonga, Tahiti, Noumea

4. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium and Carbon (Mild) Steel are determined by the following standards:

AS 4312 – Atmospheric corrosivity zones in Australia.

AS 2312.1- Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings. Part 1: Paint coatings

ISO 9223 – Corrosion of metals and alloys – Corrosivity of atmospheres – Classification, determination and estimation

5. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium are determined by the following standard:

ISO 9223 – Corrosion of metals and alloys – Corrosivity of atmospheres – Classification, determination and estimation

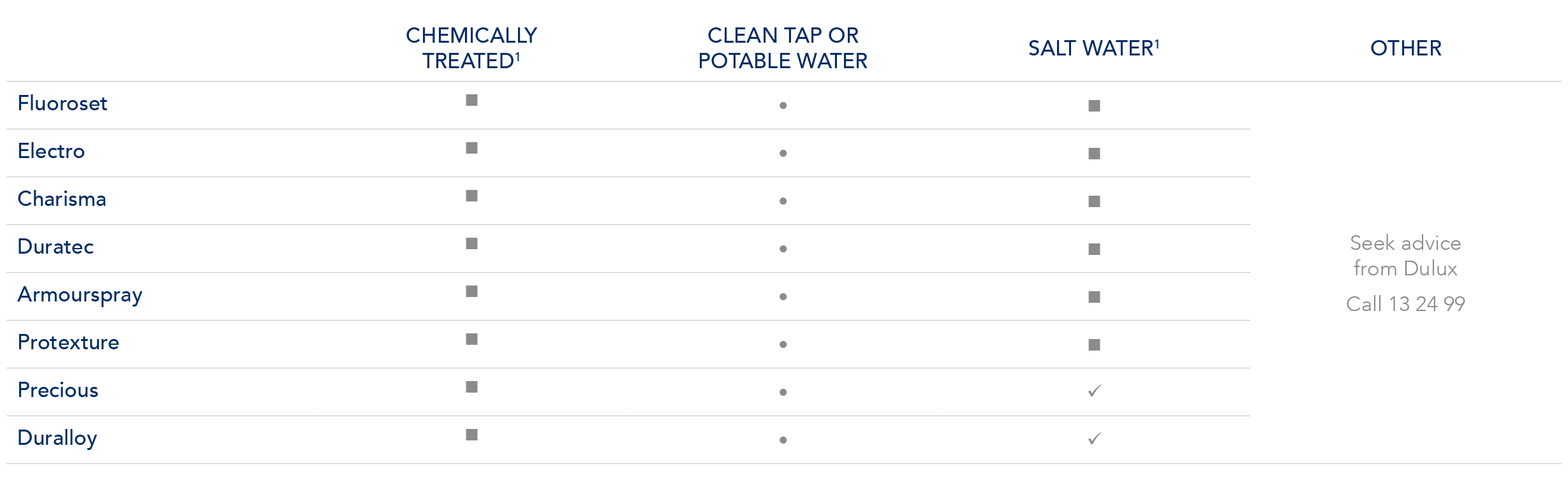

Exterior environments close to liquids other than coastal, river and lake salt water environments

For any interior application of powder coating on non-habitable projects that are close to liquids other than the sea, eg fences near outdoor swimming pools, fountains, outdoor furniture etc please refer to the guidance below for your product options for your project.

The following table can be used to help identify the product choice you have for the interior use of Dulux Premium Powder coatings on your non-habitable project.

Conditions – interior

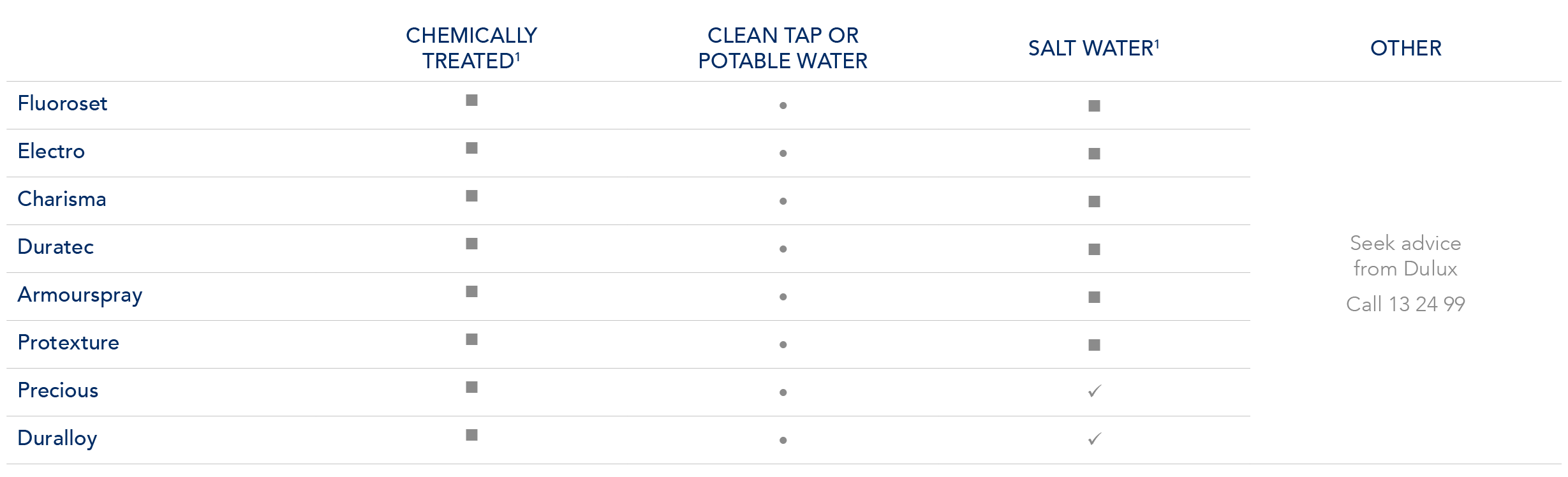

Interior environments close to liquids

For any interior application of powder coating on non-habitable projects close to liquids, eg furniture, racking etc please refer to the guidance below for your product options for your project.

1. Aggressive liquids such as Chemically Treated liquids and Salt Water must be cleaned off immediately as per the Dulux Care and Maintenance guide.

Please note chemically treated water includes antimicrobial treatments, e.g. in pools, anti-corrosive chemicals, and soapy water in bathrooms and showers.

■ Where indicated Alumi Shield and Steel Shield warranties are available on areas >than 1m from the liquid.

✓ Where indicated Alumi Shield and Steel Shield warranties are available on areas >than 2m from the liquid (ie outside the splash zone).

● Where indicated Alumi Shield and Steel Shield warranties are available any distance from the liquid.

Alumi Shield and Steel Shield warranties are only available when applied by a Dulux Accredited Powder Coater to the warranty specification on recommended project types and conditions.

All Dulux powder product are NOT suitable in strongly acidic or caustic environments so the pH must be between 5 and 9.

Alumi Shield warranties are not available if the powder coating is immersed in any liquid.